Structural behaviour

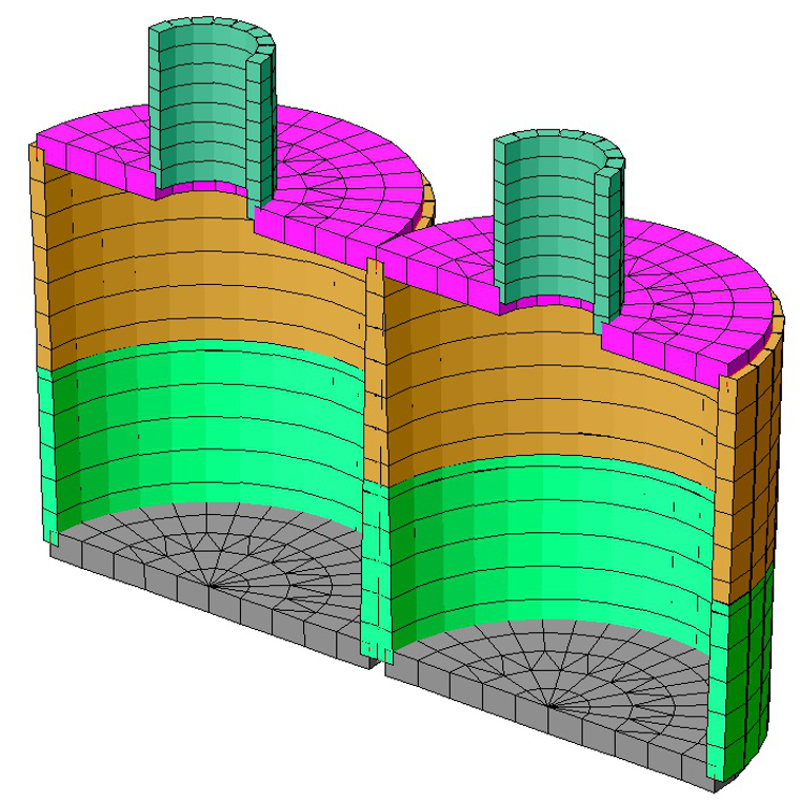

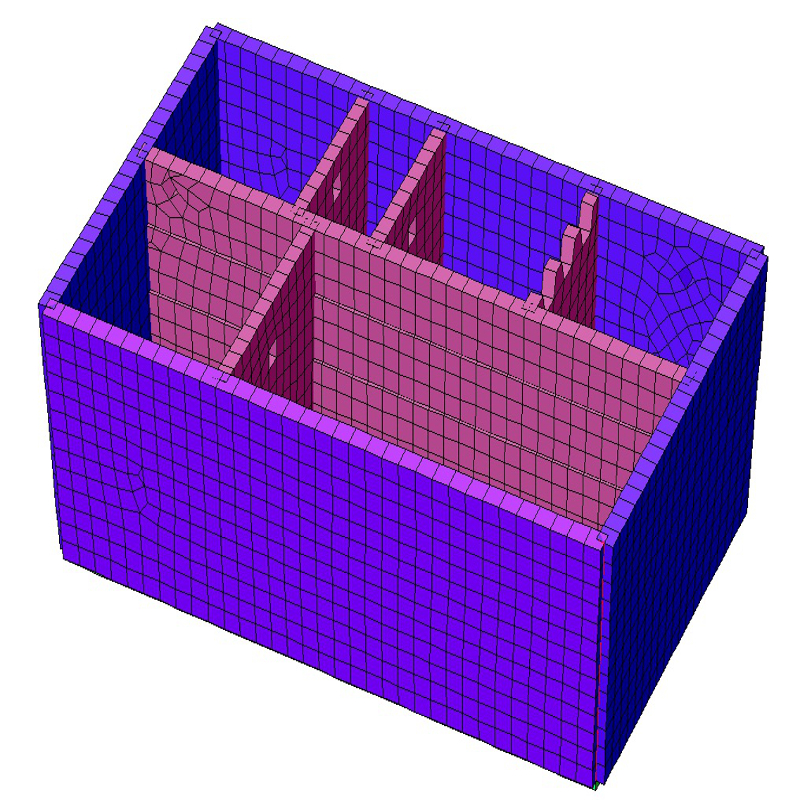

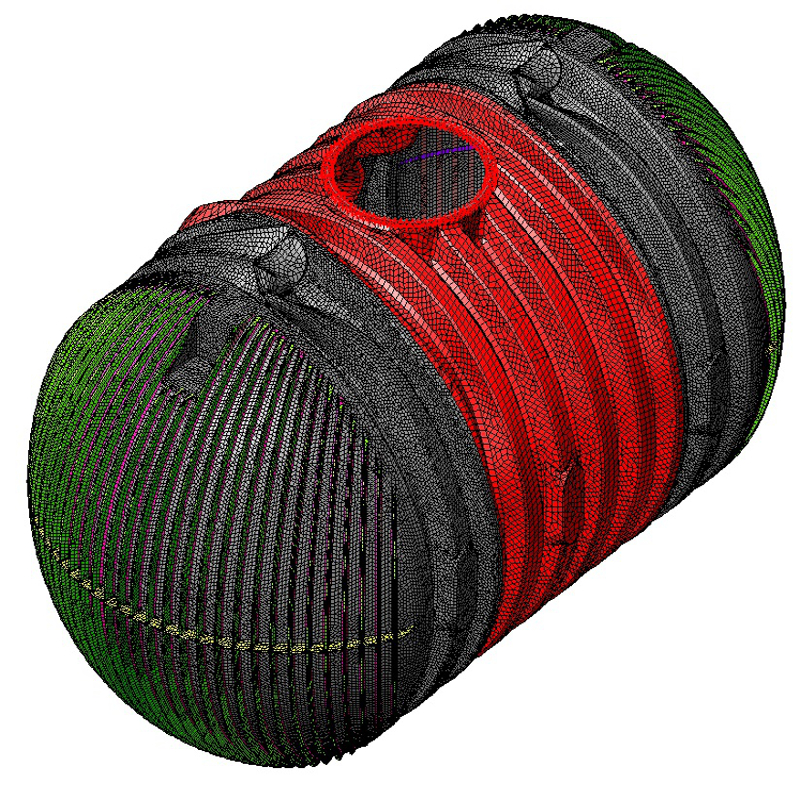

According to DIN EN 12566, small sewage treatment plants are sufficiently stable when they can withstand the stresses of handling, installation and operation – such as maintenance and sludge removal – over their entire service life. The tank may not collapse, nor may major deformations occur to an inadmissible extent. Estimated factors that influence stability are soil loads, water pressure and traffic loads as a result of pedestrian loads.

Actions on a cylindrical tank are as follows:

- p: traffic load

- wa: water pressure due to groundwater

- wi: inner water pressure

- eoh: horizontal, active earth pressure

- eohp: earth pressure due to the traffic load p

The stability can be tested in accordance with DIN EN 12566, either by a mathematical verification or by applying a testing procedure given in Annex C of the standard. The type of procedure depends on the tank material. Manufacturers can decide on their own which method should be used for the proof of stability. It is permissible to test or to mathematically verify the least efficient reservoir of a series. For each individual case and depending on the design and the installation conditions, manufacturers must carefully examine and clearly document if they choose the least favourable from a series.

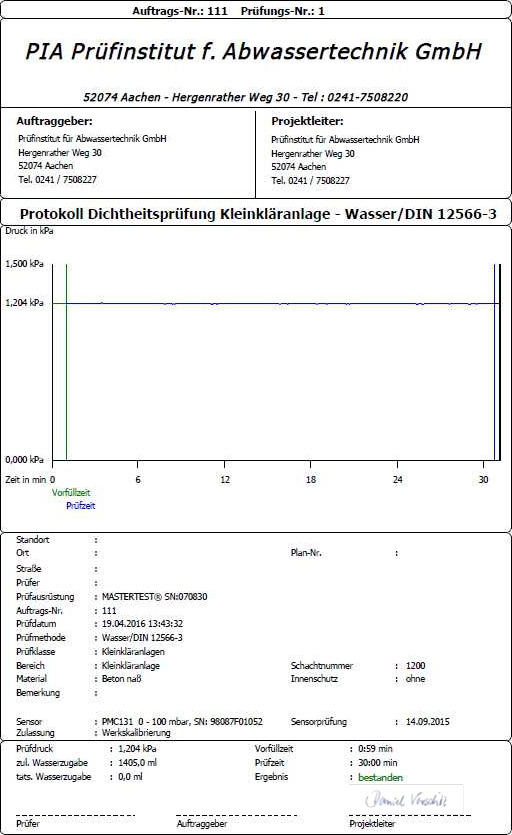

Water tightness

The plant must be watertight up to the height that the manufacturer specifies. The minimum allowable height is the upper edge of the tank. Depending on the material, the test may be carried out either with water or over or under pressure. While systems and tanks made of plastic may not exhibit leakage, tanks made of concrete may lose 0.1 l per m² of the wetted interior surfaces of the outer walls within a period of 30 minutes.

Durability

Plant, including all fittings, must be manufactured out of materials that are suitable for use in waste water. Depending on the tank material used, appropriate material characteristics are required as expressed in EN 12566, such as tensile properties of plastic or the compressive strength of concrete.

Reaction to fire

In some European countries (for example in Germany), small sewage treatment plants and the tank material used are subject to national legal requirements in terms of flammability. The class must be checked and determined according to EN 13501-1. In most cases, class E is regarded as the sufficient legal minimum requirement for fire behaviour of buried and/or underground plants.

Dangerous substances

When construction products come in contact with water and soil, they can release substances that pose a potential risk to the environment. Currently, there are only national provisions and specifications on the release of dangerous substances. Therefore, since there are no harmonised European test methods, verification and declaration regarding the release/the content should be made, while national regulations in force at the place of use are taken into account.

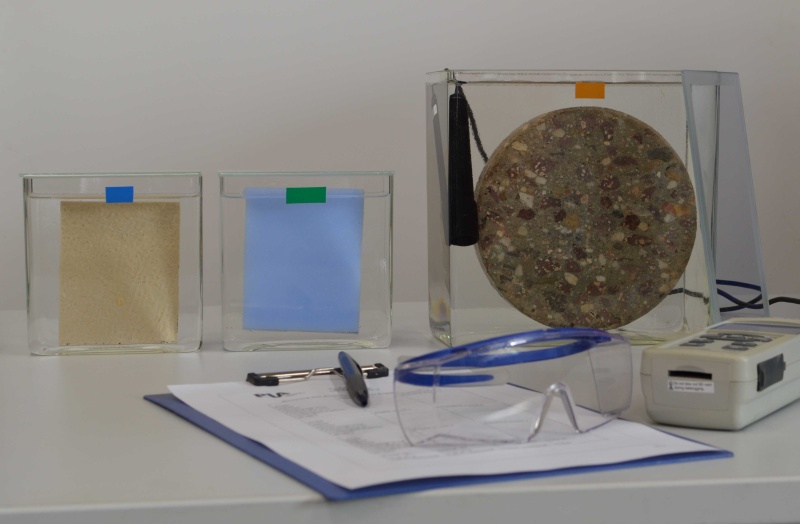

The so-called dynamic surface leaching test (DSLT) can be used to specify the extent to which inorganic and/or non-volatile organic substances are released from a monolithic, plate-like or sheet-like product. Here, parts of the building product come in contact with an aqueous solution (leaching), and the release of dangerous substances is determined over a defined period.

Additional national requirements, in particular for Germany, can be found here:

» http://ec.europa.eu/growth/tools-databases/cp-ds/germany_en

2 updated SR66 certificates online now

Clenviro Ltd. + Harlequin Manufacturing Ltd. - MATRIX CLF + CAP

KLARO + PPR Carlow - KLARO one (distributed by Wastewater Solutions)

2 new SR66 certificates online now

Tpw Systems with its new EUROTANK BAF2 and EUROTANK BAF2 +TER3 treatment systems.

1 certificate updated with new models: O'Reilly Oakstown Environmental - Oakstown Systems BAF

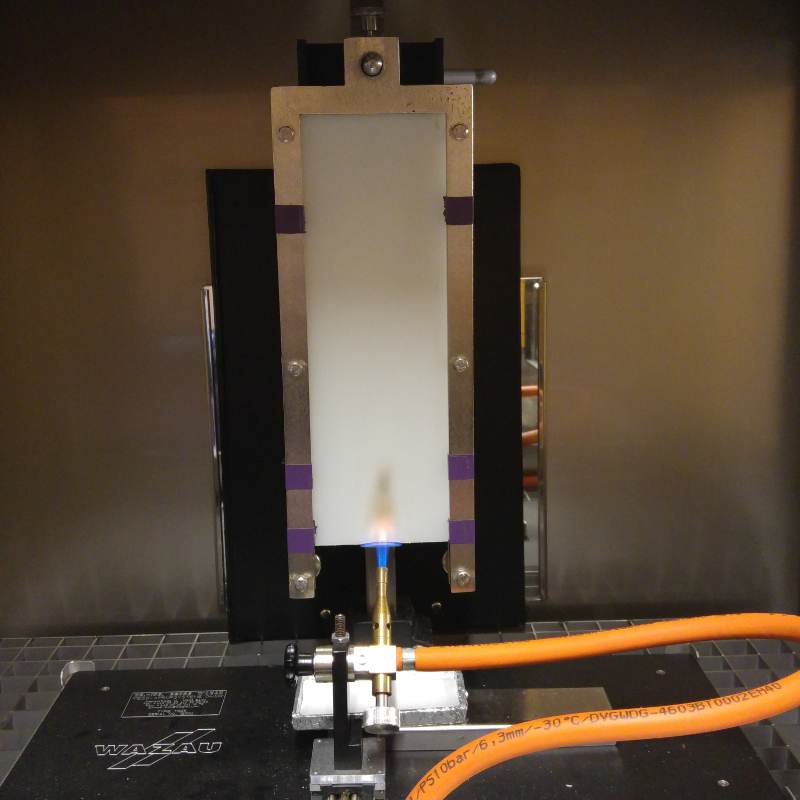

Horizontal notification for EN ISO 11925-2 - Reaction to fire

PIA GmbH is now notified for testing of the essential characteristic “reaction to fire” according to EN ISO 11925-2 (Ignitability of products subjected to direct impingement of flame / Single-flame source test).

Ignitability tests for fire classification may be conducted for all construction products under CPR Annex V.3.

Further information is available in the Material tests / Reaction to fire section.

Visit Notified Body 1739 on NANDO for notification details.

Nachweis von gefährlichen Stoffen

Norwegen fordert bis zum 31.12.2017 einen „Dynamischen Oberflächenauslaugtest“ (Dauer 64 Tage) zwecks Nachweises gefährlicher Stoffe für Kleinklärbehältermaterialien. Weitere Infos können dem Anhang entnommen werden: