The new standard DIN 30762

Sanitation systems that depend permanently on water as a transportation media might not be suitable for specific scenarios due to economical, ecological or technological reasons. Waterless sanitation systems provide the opportunity to ensure sanitation without being dependent on water supply and sewage system. Moreover, systems without water as a flush medium gain more and more interest due to good preconditions for effective resource recovery from excreta. The national standards in Germany had not covered waterless toilets, except for chemical toilets. In May 2022 the new standard DIN 30762 “Prefabricated sanitation systems without connection to water supply and sewage system – Requirements and product features” was published. Aim of the standard is to assure quality, comfort and safety of the system by determining criteria for design and constructional requirements.

The new standard applies to sanitation systems that do not require water as transportation media (SanoWa), both temporary and permanent installations. According to the norm waterless sanitation systems consist of frontend and backend. The frontend might either not be directly connected to the backend (category 1) or include pipework or direct conveyance to backend (category 2). The backend is classified either as backend for collection and storage (category 1) or backend for collection, storage and treatment (category 2). The selection of necessary test procedures depends on the classification and implemented technology within the system.

PIA GmbH does perform testing of waterless sanitation systems according to DIN 30762. The German version of DIN 30762:2022 published by Beuth Verlag can be found here, an English translation has not been published yet.

Designation as DIBt test center

Since March 2021, PIA GmbH has been a designated testing body by Deutsches Institut für Bautechnik (DIBt) for the testing of systems in accordance with the approval principles for storm water treatment systems Part 1: Systems for the decentralized treatment of wastewater from motor vehicle traffic areas for subsequent infiltration into soil and groundwater.

The testing of the plants includes the retention of fine particles with Millisil W4, the retention of mineral oil hydrocarbons and the retention of the heavy metals zinc and copper. The latter test is carried out on a scaled-down filter element. In order to obtain building authority approval for the system, a particle retention of at least 92 % and a hydrocarbon retention of at least 80 % must be demonstrated. Within the scope of the heavy metal test, the effluent values of ≤ 1,875 µg/l for zinc and ≤ 144 µg/l for copper must be complied with. In addition, heavy metals may only be redissolved by de-icing salt within specified limits.

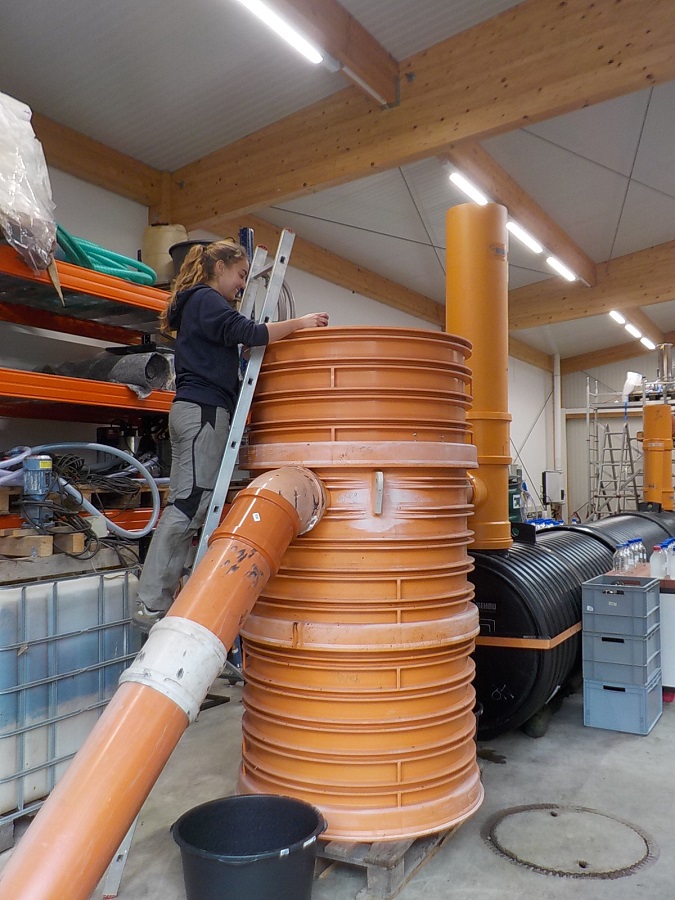

To date, ten storm water treatment plants of various designs have been tested in the test hall built by PIA GmbH for this purpose. The existing infrastructure allows the testing of plants with a connection size of up to 8,000 m². Underground storage tanks guarantee a receiving water volume of 80 m³. The discharge water is cleaned on site via buffer tanks and a light liquid separator before it is discharged into the sewer.

At the international level, test requirements vary with regard to the rainfall donors used, the pollutant load and the composition of the test media. The use of alternative test media helps to understand the effectiveness of the system under real-world conditions. For example, rubber dust can be used to represent tire abrasion and microplastics. In addition, different requirements for feeding the plant require individual solutions, which are implemented in a practical manner at the test institute.

Lecture new storm water treatment

Lecture on the current topic:

Decentralized storm water treatment in times of climate change and microplastics

Urban flash floods, the progressive sealing of soils and anthropogenic pollution such as microplastics urgently require alternative solutions in the field of precipitation water treatment. Local treatment and infiltration help to relieve hydraulically loaded combined sewer systems and to take targeted action at the point of pollution. Decentralised rainwater treatment plants can offer an alternative. In Germany, but also in other countries, requirements are therefore already being placed on these systems and tested under laboratory conditions. The lecture shows the current problems, gives an overview of the different treatment systems and their possible applications, and presents the test requirements and the tests.

Speaker: Daniel Verschitz, Time: 24.02.2021 at 10:00 a.m., Language: English

Duration: Max. approx. 30 minutes each + 10 minutes questions / discussion / feedback

If you are interested, you can register here:

https://www.atbwater.com/en/about-us/events/online-seminars/

Decentralised storm water treatment

British Water has published the Code of Practice "Assessment of Manufactured Treatment Devices Designed to Treat Surface Water Runoff".

More information is available here: https://www.britishwater.co.uk/publications/manufactured-treatment-devices.aspx