CE tests according to EN 12566

The basis for a successful market entry in Europe is the CE marking of your product. For this purpose, the series of standards – EN 12566 – is used. Five of the seven standards have been harmonised and, with our support, you can receive a declaration of performance according to one of these standards and place it on your product. With it, small wastewater treatment plants can be traded legally throughout Europe.

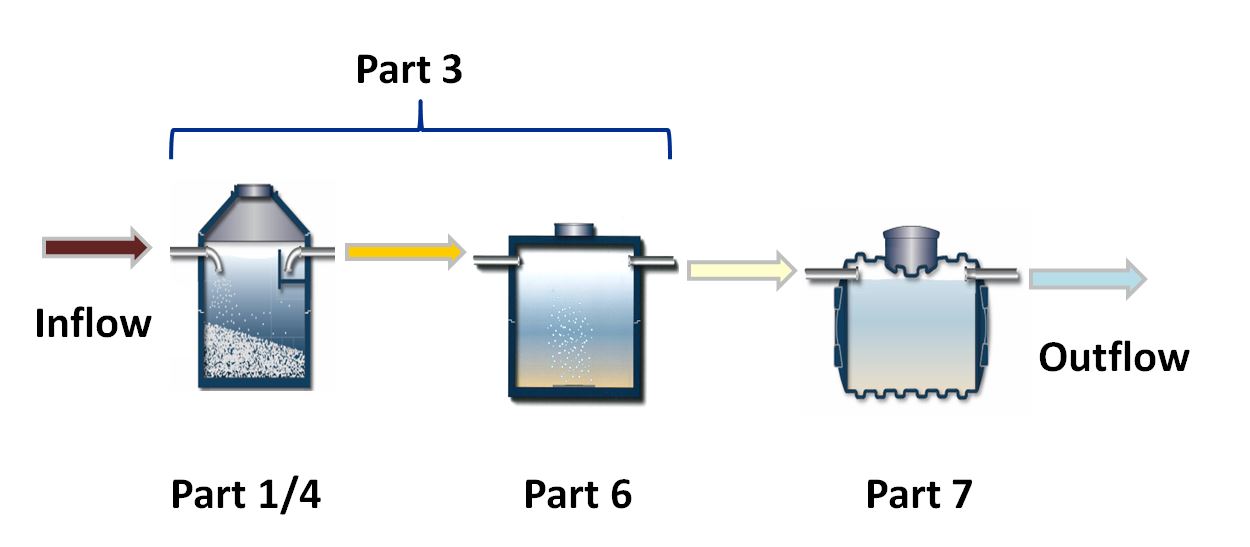

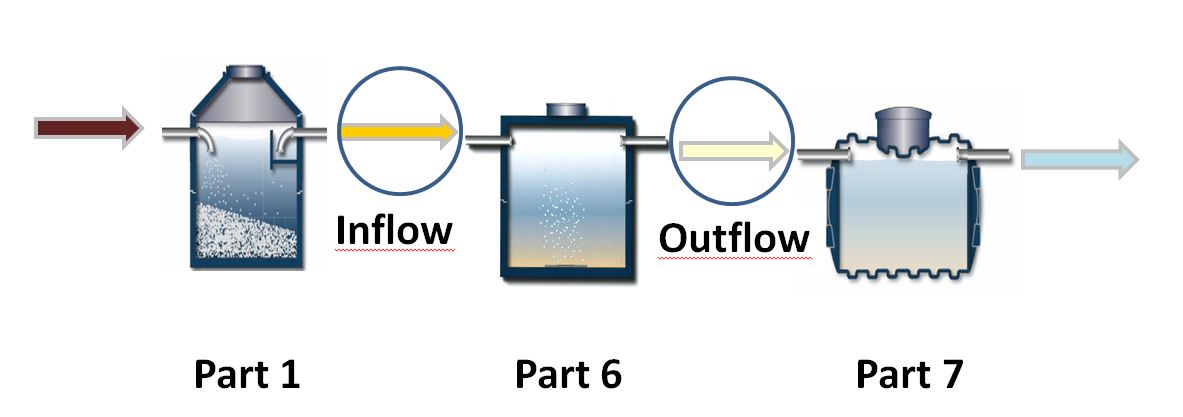

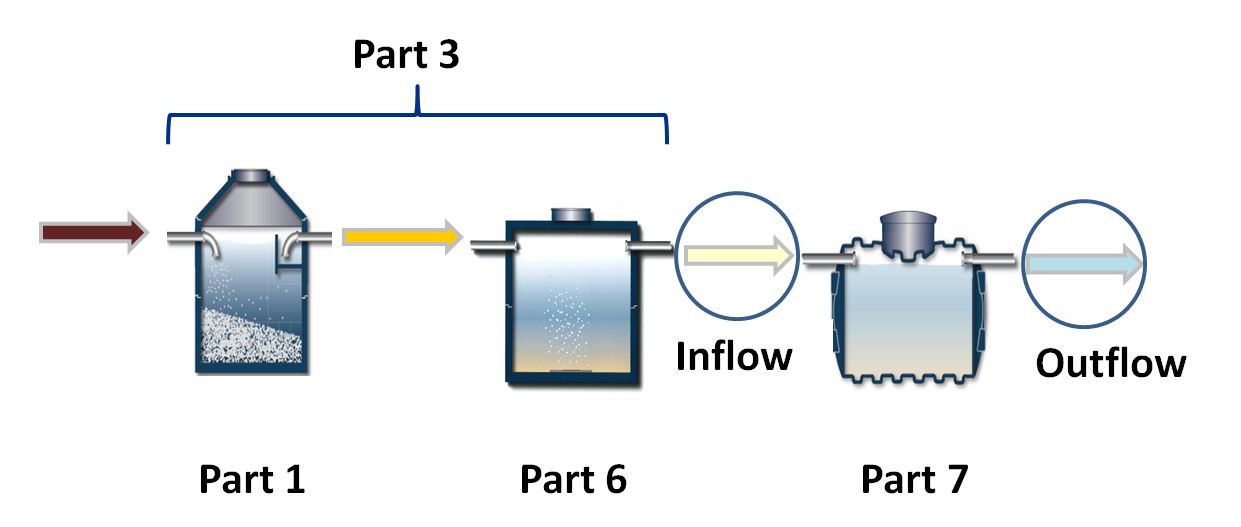

The standard EN 12566 is divided into several parts, each of which defines the basis for the respective tests:

Part 1: Prefabricated septic tanks

Additional tests for septic tanks according to EN 12566-1

Daniela Schmitz, M.Sc.

Defining the nominal capacity

Along with the water tightness test, the usable volume of a septic tank must be measured and defined. To do this, the volume of water is measured at the height of the outlet with a calibrated measuring device (magnetic induction).

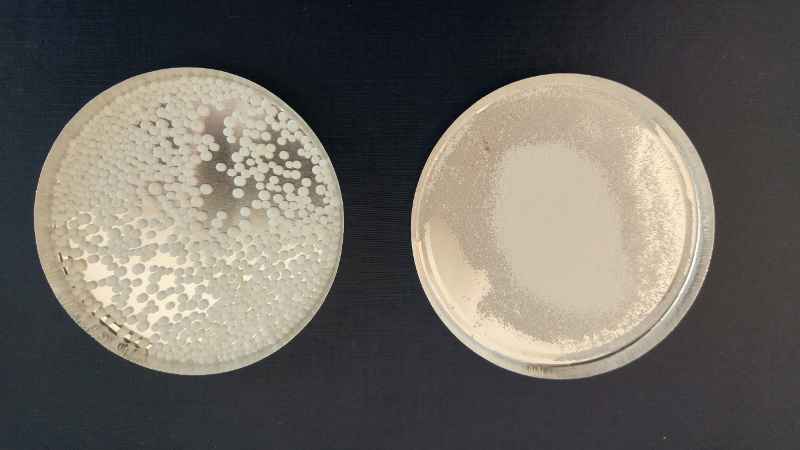

Test of the hydraulic efficiency

The hydraulic efficiency is used to measure of the retention of the settleable solids and floating material from septic tanks. To do this, polystyrene beads are utilised to simulate the settleable solids and floating matter. The result is expressed by the amount of polystyrene beads collected in the effluent of the septic tank in grams.

Part 3: Packaged and/or site assembled domestic wastewater treatment plants

The important standard EN12566-3 is used to test constructed wetlands and small wastewater treatment plants with biological purification for the European market. As with septic tanks, the plants are checked for stability, water resistance and durability. In some cases, the plant’s reaction to fire and the possible release of dangerous substances is also tested.

The significant test of the treatment efficiency is carried out in PIA’s test field over a period of 38 weeks. Once delivered, your treatment plant is placed in the test field by the PIA team and charged with domestic wastewater. After the necessary start-up phase, in which the biological process begins running, the actual testing of cleaning performance begins. Emerging requirements for desilting should be considered when new tests are conducted. Secure key advantages of your plant and talk to our experts.

Part 6: Prefabricated treatment units for septic tank effluent

In addition to testing the septic tanks as a first treatment stage in accordance with EN 12566-1, you can also individually CE-mark the second treatment stage so that you can place them on the market. Plants of the second treatment stage (usually bioreactors), which generally treat wastewater coming from septic tanks, are tested according to the relatively new standard EN 12566-6. Here too, the 38-week test with different test modes is used to verify the treatment efficiency. The tests of the tank, however, are carried out according to the standard EN 12566-3. We can show you various combinations so that you can reduce costs. Talk to us.

Part 7: Prefabricated tertiary treatment units

EN 12566-7 defines the requirements for prefabricated tertiary treatment units for small wastewater treatment systems. The procedures described in the standard enable a further purification to improve the quality, which cannot be achieved by the first treatment stage (primary treatment) and the second treatment stage (biological treatment) alone. The third purification stage and its plant modules are usually not independent treatment systems. They are only used in combination with a primary clarification and a biological treatment and concentrate on a specific treatment objective, such as the additional reduction of phosphorus or nitrogen.

Depending on the type of process, two different test sequences are prescribed for determining the cleaning performance. The test duration for chemical and electrical processes is seven weeks, for biological and physical processes 16 weeks. For the test, the manufacturer specifies the daily inflow and the daily pollution load for COD, BOD, SS and the parameters that are in focus for the plant. The inflow dynamics are also relevant. This is usually oriented either to the flow diagram of an SBR system or a gravity-flow system and thus also specifies the later area of application. The transferability of the performance of the plant to other inlet conditions is generally not possible. Therefore, in order to make the application of small sewage treatment plant modules for the third purification stage meaningful, it is necessary to also specify the inflow conditions during the test in addition to the results and the specific purification target that is in focus.

- Biological processes:

Treatment mainly by microorganisms

Priority objective: reduction of COD, BOD, SS and nitrogen - Physical processes:

e.g. by filtration

Priority objective: reduction of SS and phosphorus - Chemical processes:

Treatment mainly by addition of chemical substances

Priority objective: reduction of SS and phosphorus - Electrical process:

Treatment mainly by the use of electricity

Primary objective: Reduction of microorganisms

The following manufacturers have successfully performed a test according to EN 12566-7 at PIA GmbH and agree to be listed on this website:

| Name of manufacturer | Name of product | End of testing |

|---|---|---|

| batchpur | UV Modul | May 2018 |

| batchpur | C4C | May 2018 |

| Bokatec (batchpur) | batchpur +P | June 2014 |

| Bioptech | Fosforfilter Polonite® | August 2015 |

| Biovac | Haco vannmettet EP-5PE | March 2016 |

| Europhat | EP 5 | May 2020 |

| FANN | FTK 503 | August 2015 |

| Ireland Waste Water | Circle 7 | March 2019 |

| KLARO | blue.cycle / KL Sandfilter | June 2016 |

| KLARO | KL chlorination+ | December 2016 |

| Molloy Environmental Systems | Chieftain Coco filter | April 2021 |

| Senex | ATPU | August 2019 |

| Tpw Systems Ltd. | Eurotank Ter3 | June 2022 |

| utp | sbf - Filter | March 2019 |